Custom Software

Dynamic Systems is a fully capable software developer. Along with our suite of available applications for manufacturing work-in-process, ERP integration, custom-directed pick and pack and other key functions, our programming staff can craft software to fit your own special process requirements.

Inventory Solutions

For manufacturing or distribution companies, inventory can be the largest asset. It’s important to keep an accurate inventory for many reasons – avoid stock outages; manage losses and obsolete inventory costs; assure that your customers get what they need quickly. Dynamic Systems has several solutions for companies wanting to automate their inventory tracking system.

Mobile Inventory Tracking

Advanced Logistics – Dynamic Systems offers an inventory application using mobile barcode scanners, tracking your products from receiving through shipping. This Android application keeps track of your inventory using fast and accurate barcode scanning with rugged equipment that works in wet and cold environments, and it can integrate with your accounting or ERP system to automatically update inventory levels.

- Store inventory items to specific locations for easy retrieval

- Use barcode scanners to take regular inventory counts

- Record shipments against sales orders

Automated Data Collection

If you have an existing inventory application, we can recommend the best barcode equipment to automate your warehouse. With more than 35 years’ experience in inventory processes, we can help streamline your operations and save you time and money.

- Improve efficiencies with barcode data collection

- Select the best mobile or fixed scanners and printers for your environment

- Produce rugged labels for shelf locations and products

Directed Pick & Pack Verification

Dynamic Systems has a solution for smaller to mid-sized companies who want more accurate picking and shipping operations. Save time and money, making sure your team quickly finds the warehouse items they need to pack exactly what your customer has ordered.

Directed Pick

Do your warehouse workers have trouble finding the items they need to fulfill an order? By using Directed Picking in conjunction with our Inventory application, your people will be told which location in the warehouse has the product they need. The system uses FIFO (First In/First Out) to determine the oldest inventory item, a feature especially important in industries like fresh foods. Save time searching, speeding up the picking process.

What Is Pack Verification?

Packing errors are common in a high velocity warehouse. When workers misread labels or pull the wrong item, your customers don’t get what they ordered. When customers get extra items you hope they will let you know, but if they don’t get what they ordered, you can be sure they will let you know! In either case it costs you time, money and potential goodwill.

With our Pack Verification option your workers will scan the item they pick. The software will tell them whether it’s the correct item or not, eliminating the guesswork and speeding up the picking process. Your customers will get what they ordered, while you will save money in both time and inventory shrinkage.

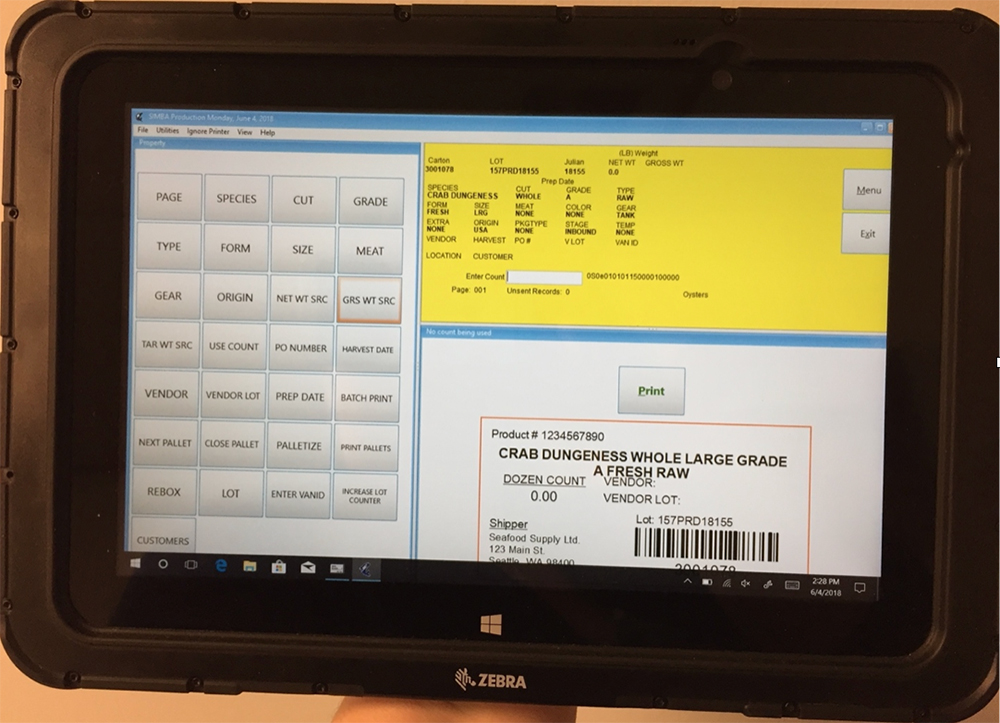

SIMBA: Labeling, Tracking and Tracing of Fresh Foods

For 15 years, our SIMBA system has been a gold standard for barcoded inventory solutions in fresh seafood, meat and produce, where perishability makes inventory tracking essential, and where strict food safety regulations require complete traceability of every product.